Medium Wave Quartz Infrared Heaters Manufacturers

Medium Wave Quartz Infrared Heaters Manufacturers

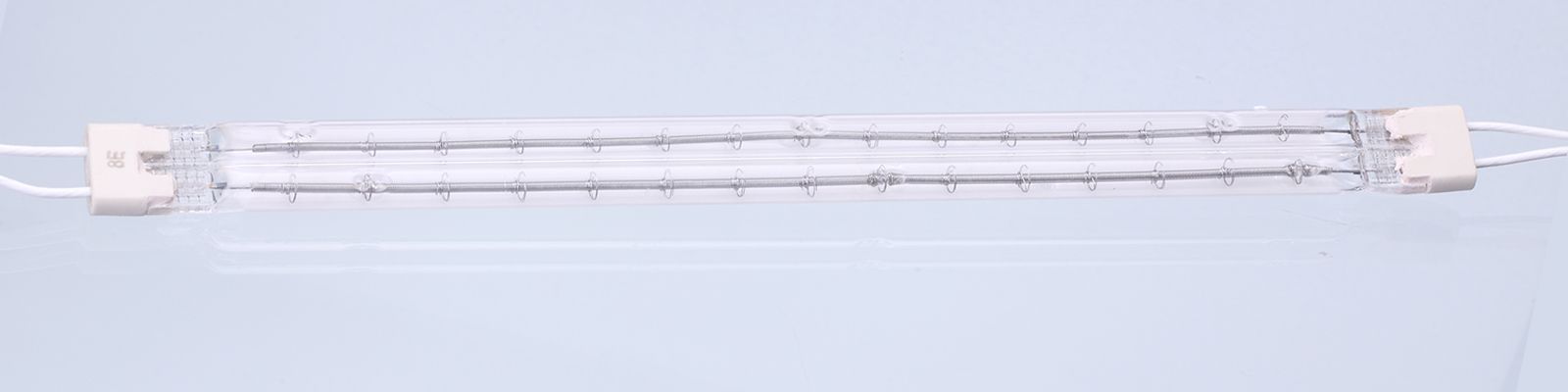

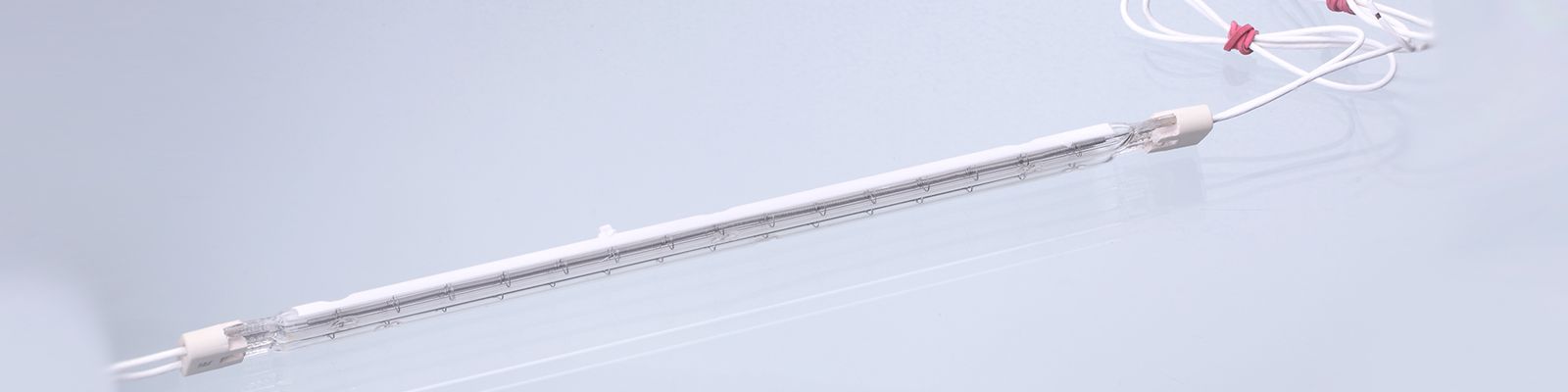

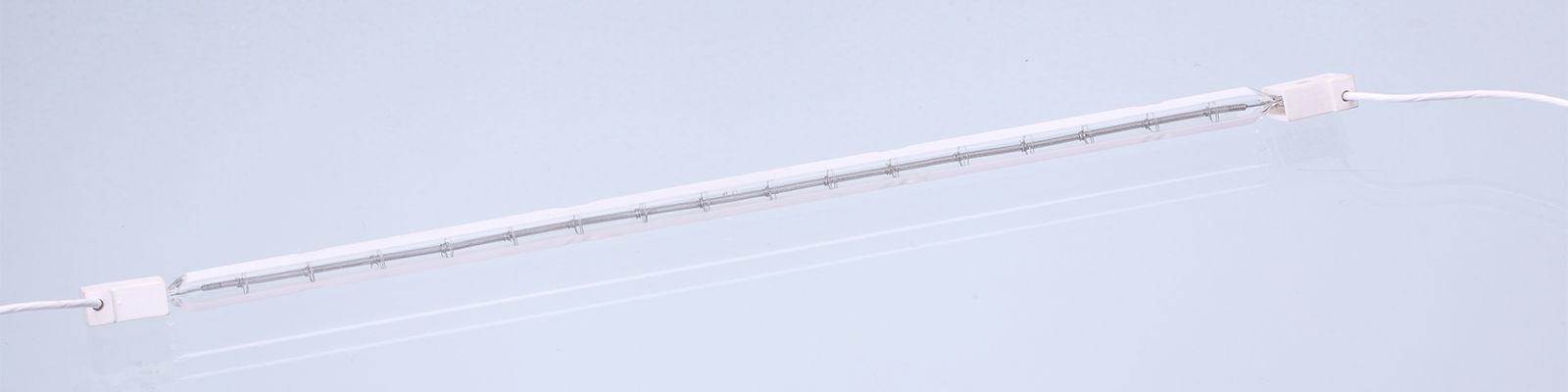

Medium wave quartz infrared heaters manufacturers are not only innovators in energy-efficient heating solutions but also pioneers in cutting-edge technology. Buy Medium Wave Quartz Infrared Heaters These companies strive to not only meet but also exceed industry standards, ensuring the highest level of performance and reliability in their products Quartz Infrared Heaters Manufacturers in India Quartz Infrared Heaters Manufacturers in India Quartz Infrared Heaters at best price Quartz Infrared Heaters at best price.

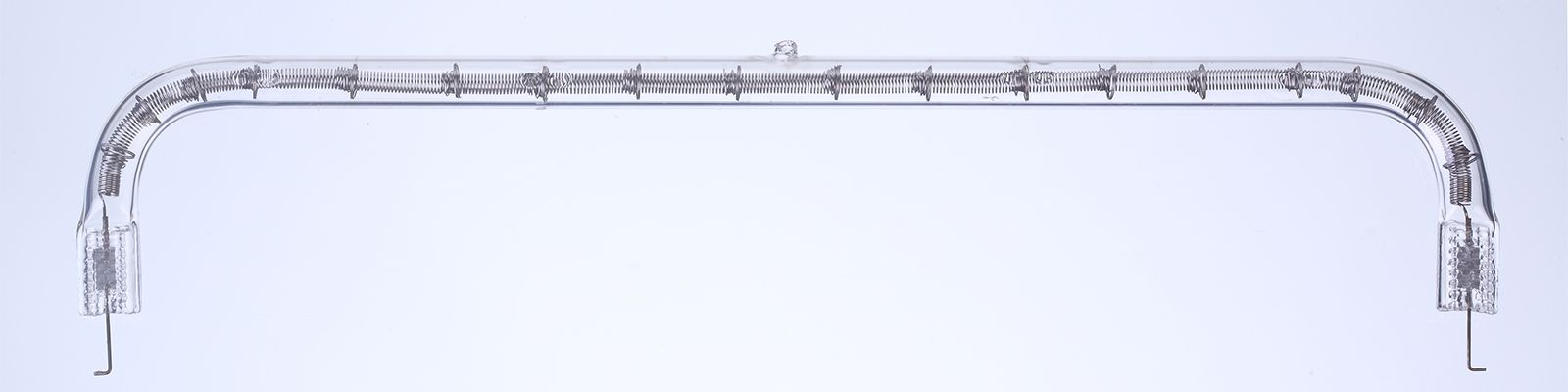

Not only do these manufacturers prioritize functionality, but they also place a strong emphasis on design aesthetics, ensuring that their heaters not only heat effectively but also enhance the ambiance of any space they inhabit. One key advantage of medium wave quartz infrared heaters is not only their ability to heat objects directly but also their rapid response time, providing instant warmth when and where it’s needed most Buy Medium Wave Quartz Infrared Heaters.

Work of Infrared Lamp Manufacturers providing essential equipment

not only invest heavily in research and development but also collaborate closely with experts in the field to continuously improve their products and stay ahead of emerging trends. These companies not only produce heaters for industrial applications but also offer a diverse range of solutions for residential, commercial, and outdoor heating needs, catering to a wide array of customers.

Not only are highly efficient, but they also boast a longer lifespan compared to traditional heating methods, offering cost savings over time. Manufacturers not only adhere to stringent quality control measures but also subject their heaters to rigorous testing to ensure durability and performance under various conditions.

In addition to their heating capabilities, medium wave quartz infrared heaters not only emit minimal light but also produce little to no noise, making them ideal for environments where comfort and tranquility are paramount. These manufacturers not only prioritize environmental sustainability but also strive to minimize their carbon footprint through the use of eco-friendly materials and energy-efficient manufacturing processes.

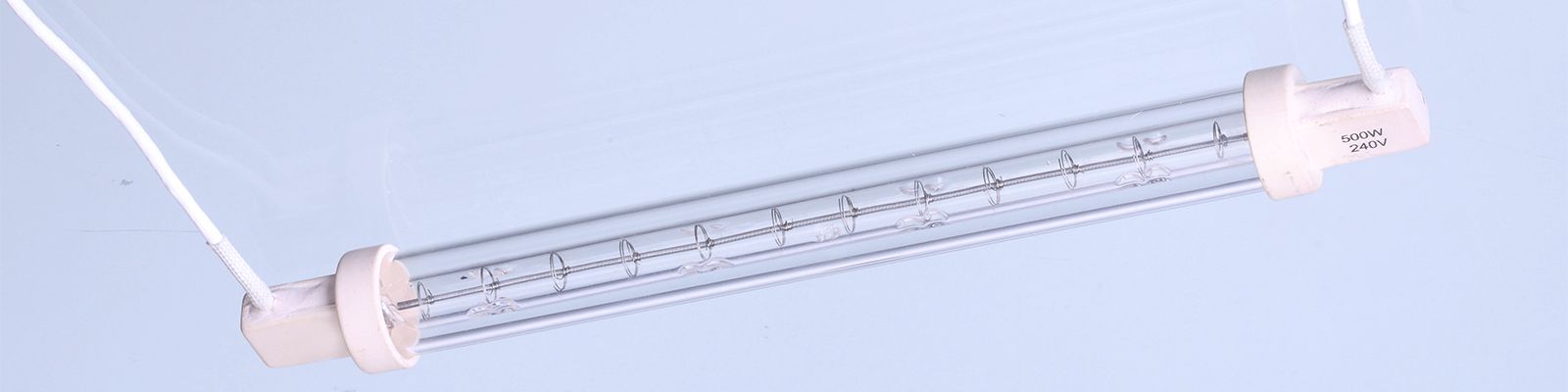

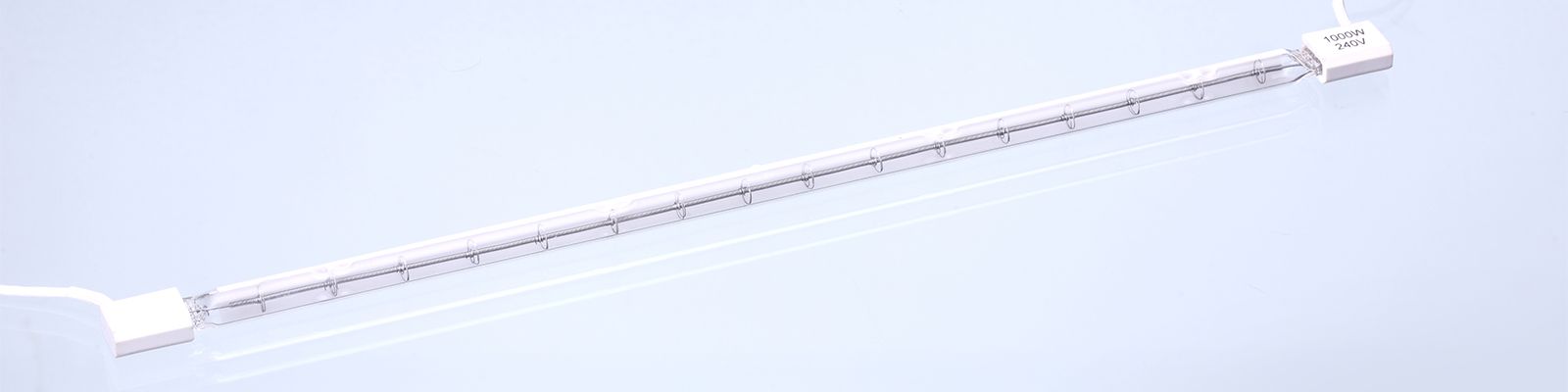

Litex Electricals is No. 1 and one of the well-known Medium Wave IR Heater Manufacturers In India. We ensure the unbeatable performance and top-grade quality of the Medium Wave IR Heater.Actually, they are both infrared heaters, except quartz heaters emit higher temperatures with resistance wire inside a quartz tube. A quartz heater can reach the temperature for which it is designed in less than a second; however, this time and temperature can be hard to control.Useful wavelength range: 1.5 – 8 microns. Recommended radiation distance from heater is 100 mm to 200 mm.Electric quartz heaters consume less energy than ceramic heaters to produce the same results. Because quartz heaters directly transmit the energy and do not rely on convection heating, they are better than ceramic heaters at targeting their heat to specific areas. Unfortunately they produce an intense and fierce heat, which is a cause of complaints by users (“dry eyes”, burning sense, unpleasant light).